Purus channel asphalt

DEVELOPED FOR PARKING GARAGES, GARAGES AND WORKSHOPS

IDEAL DRAINAGE

Whether you are looking for drainage in a large multi-storey car parking garage, a small garage or a workshop – we have a suitable solution. Our stainless steel Purus channel asphalt is designed to be easy to install together with asphalt paving, pulp or concrete, has a simple and stable construction and a high flow.

CUSTOMIZING IS OUR EVERYDAY LIFE

Purus channel asphalt was developed in dialogue with those who know the job – the professionals who perform the waterproofing and coating work. They told us about their usual challenges, which guided us in our product development.

Nowadays, we usually establish a dialogue with the asphalt contractor to ensure that the construction is the best imaginable in terms of long life and minimal maintenance effort. For channels over 2.5 m, they are manufactured in sections and then screwed together on site. The gaskets used when they are screwed together can withstand high temperatures, chemicals such as salts and oils and is UV-stable.

GOOD MOUNTING WITH ADAPTED FLANGE

Purus channel asphalt is made of acid-resistant stainless steel for installation in concrete floors with a coating in the form of cast asphalt, asphalt concrete, pulp or concrete. The channel is adapted as needed; with regard to which surfaces are to be drained, what the construction process looks like and in which environment with associated load the product will be exposed.

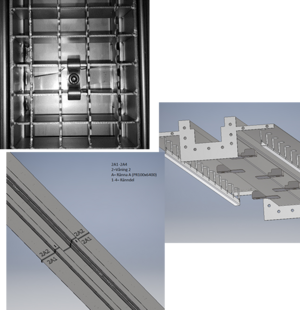

In standard version, the product has an anchor bracket for easy installation and height adjustment. These are adapted to get a very good attachment to the concrete. For channel parts that are placed in the carriageway, we recommend choosing the grip strip as an accessory, to ensure the wide bitumen flange attaches firmly to the concrete. The gutter can be fitted with non-slip grate in load class L15 which holds for passenger cars or M125 for heavier vehicles

REFERENCE OBJECT KUNGSBACKA

Purus has produced 767.7 m of specially built stainless steel channels for the parking garage, which was completed in 2021 in Kungsbacka. For the project with casting in light asphalt, a number of product adjustments were made in dialogue with HVAC managers from Caverion. Here are some of them:

1. New locking device for the grates.

Customized locking device for locking grates in the channel. This is for an increased displacement margin, as the channels are welded together on site and as a safety measure so that the grates do not move during traffic.

2. Spot welded grip strip and robust flange

The flange’s task is to ensure a tight connection to the bitumen mat. The flange must be firmly anchored in the concrete, so that no movement occurs during repeated traffic. This is especially important when choosing light asphalt, as any repair can be seen immediately. An extra strip was welded to the asphalt flange to make the concrete grip firmly in the flange when casting.

3. Identification number

At the end of all channel parts, specific ID numbers were set to simplify and speed up the assembly, as well as reduce the margin of error around which details belonged to which part. The number indicated on which floor, to which channel and specific place the unique part would belong.

As Purus channel asphalt belongs to our special range, there is no gutter guide available at the moment. You are welcome to contact us for a solution proposal and price.

“IT IS NOT EVERY DAY I HAVE A CUSTOMER WHO CHOOSES LIGHT ASPHALT FOR A PROJECT”

Conny Hallberg, Sales Manager, stainless steel channels & gullies, Purus AB Sweden